i-Stock WMS

Warehouse Management Systems (WMS) offer a multitude of benefits that significantly enhance the efficiency and effectiveness of warehouse operations. These systems are crucial for modern, smart warehouse setups, providing end-to-end visibility and control over the supply chain. Here are some key benefits of implementing a WMS:

-

Optimized Space and Lower Operating Expenses: WMS helps in analyzing and utilizing floor space effectively, thereby reducing waste and operational costs. This optimization leads to less unnecessary material movement and more efficient product placement and retrieval.

-

Improved Inventory Visibility: A WMS provides real-time, accurate inventory levels, enabling better supply estimation and avoidance of backorders. This leads to higher customer satisfaction.

-

Efficient Labor Management: WMS optimizes labor by assigning tasks based on workers' skills, location, and available equipment, thereby improving labor utilization and reducing costs.

-

Traceability of Materials: WMS allows for detailed tracking of inventory materials using lot, batch, and serial numbers, enabling full traceability which is crucial for accurate planning, allocation, and recall situations.

-

Optimized Supply Chain: By improving internal warehouse operations, WMS extends its benefits to the broader supply chain, enhancing efficiency and savings.

-

Enhanced Order Fulfillment: WMS provides visibility into inventory levels and locations, streamlining the picking and packing process, and improving order fulfillment times.

-

Real-Time Data Analytics for Inventory Management: The system offers real-time data analytics on stock levels and locations, aiding in effective inventory management and reducing the need for cyclical tasks.

-

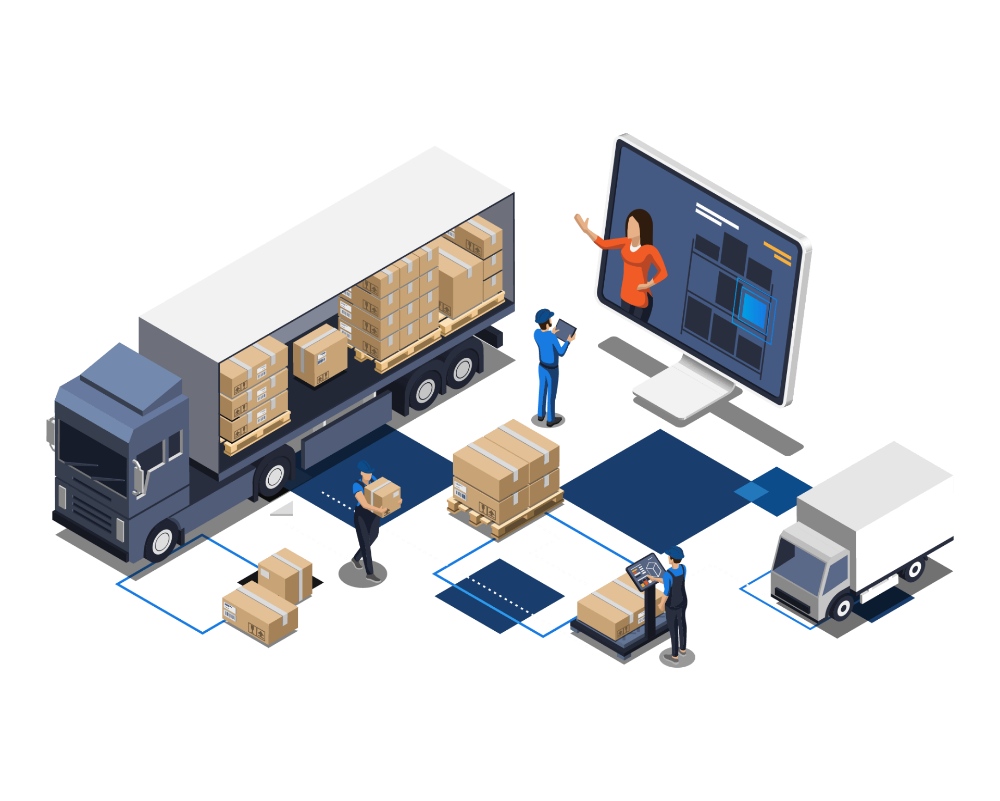

Improved Tracking of Shipments and Deliveries: WMS features real-time visibility and automated alerts for shipments, improving delivery performance and customer satisfaction.

-

Automated Warehouse Processes: Automation of manual tasks like picking, packing, and replenishment improves efficiency and accuracy, reducing costs.

-

Integration with Other Business Systems: Integrating WMS with systems like ERP and TMS achieves greater efficiencies in warehouse operations, optimizing the supply chain performance.

-

Error Reduction and Improved Accuracy: Automated processes and real-time data reduce manual errors, improving accuracy in warehouse operations.

-

Cost Savings: By optimizing operations and reducing manual labor, WMS contributes to significant cost savings.

WMS systems are versatile and can be standalone, cloud-based, or integrated into ERP and supply chain management platforms, each with their own advantages. The adoption of smart warehousing technologies, including AI, machine learning, and automation, is transforming warehouse operations to be more efficient and responsive to changing market demands and customer expectations

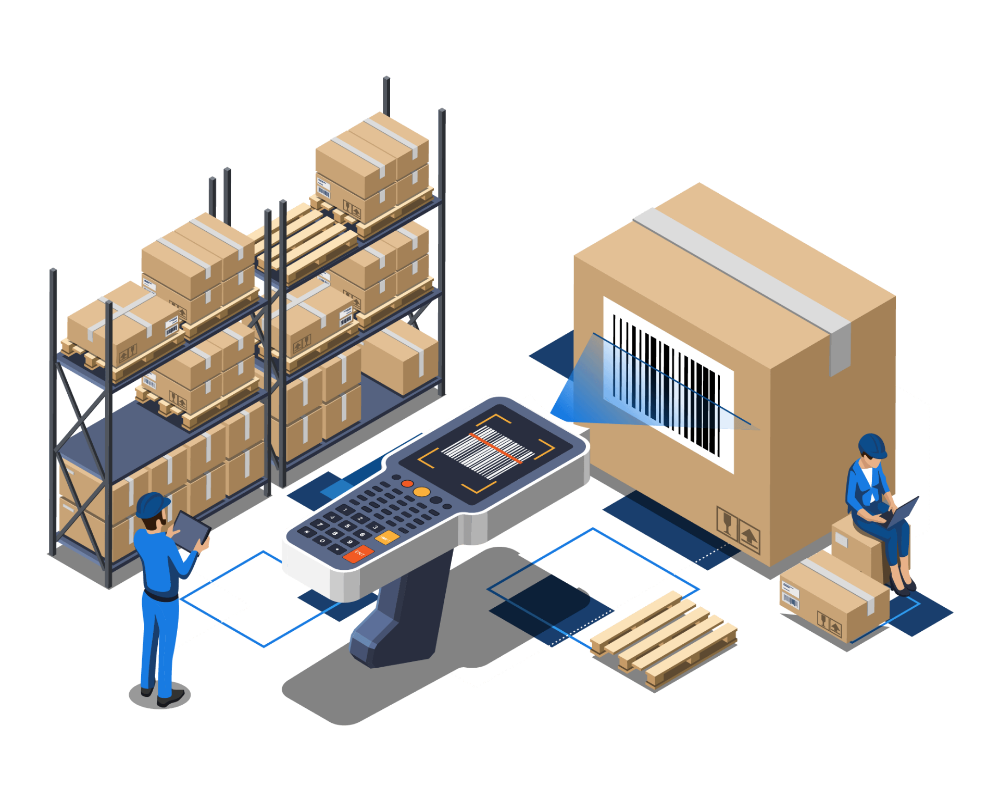

| WMS Principle | ||

|

|

|

|

Goods Receiving |

Store Keeping |

Outgoing & Delivery |

|

It is considered to be the first process that occurs in the warehouse. When products are brought into the warehouse Staff will count and record every product. Using barcode technology |

The WMS system comes in to help. The program searches for information to find appropriate product storage locations. Store products to fit in each area. Help calculate and plan To be able to use the space to the greatest benefit. |

Used to help with picking up and shipping products. It's done easily and quickly. Where are the products stored in the warehouse? To prevent erroneous delivery and speed up transportation. |

Warehouse Management Systems (WMS) are well-suited for a variety of business types and sizes, each with specific inventory and operational needs. Here's how WMS can be beneficial for different kinds of businesses:

-

Retail Businesses (Buy-and-Sell Focused, with Multiple Branches): WMS is ideal for retail businesses that focus on buying and selling products and need to manage inventory across single or multiple store locations. It helps in maintaining accurate stock levels, facilitating efficient replenishment, and ensuring product availability across all branches.

-

Businesses with Large Warehouses (Less than 15 Concurrent Users): For larger businesses with extensive warehousing needs but a relatively small number of system users, WMS can efficiently manage complex inventory systems. It's capable of handling a vast array of products and supports streamlined operations despite the limited number of concurrent users.

-

Medium-Sized Warehouse Operations (Less than 6 Concurrent Users): WMS is also suitable for medium-sized businesses that require robust inventory management but have fewer users interacting with the system simultaneously. It can provide comprehensive inventory control and operational oversight for medium-scale operations.

-

Network Designers within a Single System: For those looking to design network systems within a single organization, WMS can be integral in linking various data points and operational processes. It can centralize control and provide a unified view of the entire warehouse operation.

-

Network Designers for Internal and External Organizational Linking: WMS can also be beneficial for designing networks that link internal and external data across various departments and external partners. It enables the integration of warehouse data with other business systems, such as ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management), facilitating seamless operations within and outside the organization.

In summary, WMS is a versatile tool that can cater to the diverse needs of different business models, particularly those requiring efficient inventory and warehouse management. Whether it's for a small retail operation, a large warehouse, or an interconnected network system, a WMS can provide the necessary tools to streamline processes, improve accuracy, and enhance overall operational efficiency.